Unscheduled downtime in the production of woven fabrics results in lost time and costs that directly affect production profitability.

In this context, managers face daily challenges such as quality control failures, frequent corrective maintenance, and manual processes prone to errors.

Automated weaving machines, equipped with 4.0 technology, anticipate these problems, generate intelligent data for decision-making, and consequently optimize the entire production chain.

Preparation and Inspection: Critical Weaving Stages for Quality

The production of woven fabrics involves several steps from raw material to the final product. However, two of these steps are crucial for operational success: preparation and inspection.

These stages help ensure quality and reduce waste, preventing problems from multiplying throughout the textile production chain.

Moreover, they promote a predictable operation, capable of meeting deadlines and maintaining the brand’s reputation.

That’s why investing in modern weaving machines for these stages is a strategic necessity for those seeking competitiveness and efficiency in the market.

Learn more below!

1. Preparation of Woven Fabric

To start the weaving process, woven fabrics must be properly prepared. This means ensuring correct sizing to avoid tension, tangled threads, and shrinkage.

This way, the entire operation flows smoothly in subsequent stages, such as spreading, cutting, and finishing.

When preparation is carried out automatically, manual adjustments are eliminated, and consequently, defects are reduced.

> Also read: Textile fabric: main types and innovations

2. Inspection of Woven Fabric

The inspection of flat fabric is the stage aimed at detecting defects in the pieces, such as broken threads, weave flaws, stains, and width variations.

The goal is to identify these issues to ensure better quality control and, consequently, promote:

- Reduced rework;

- Lower return rates.

Outdated equipment and manual fabric inspection processes cause errors and compromise entire batches, leading to financial losses for the industry.

> Also read: Why does your production need a Delta textile machines?

What Are the Main Challenges in Weaving?

Weaving woven fabrics is a complex process that requires precision.

However, even well-structured operations face bottlenecks that compromise efficiency and profitability:

- Unscheduled machine downtime: every minute of stoppage represents money lost;

- Frequent corrective maintenance: generates high costs for parts and emergency labor, as well as prolonging downtime;

- Manual quality control: relying solely on human visual inspection leaves room for errors, rework, material waste, and end-customer dissatisfaction;

- Lack of data integration: without consolidated, real-time information, it is impossible to identify patterns, predict problems, or optimize processes.

How Does Automation Transform Woven Fabric Production?

Textile automation in weaving machines turns quality control from a reactive process into a preventive strategy.

Instead of merely identifying defects after they occur, intelligent equipment continuously monitors production, anticipating issues to prevent greater losses.

Industry 4.0–driven machines use high-definition sensors and integrated systems to evaluate critical aspects of woven fabrics in real time, such as thread tension, weave uniformity, and defect detection.

According to McKinsey, by 2025 the adoption of Industry 4.0 processes can:

- Reduce industrial maintenance costs by 10% to 40%;

- Decrease energy consumption by up to 20%;

- Increase operational efficiency by up to 25%.

For your weaving operation, this translates into lower operational costs, higher production capacity, and sustainable competitive advantage in the market.

Investing in intelligent weaving machines is a strategic decision that directly impacts your industry’s profitability.

Delta Weaving Machines: Technology That Solves Your Bottlenecks

Weaving machines aim to:

- Ensure quality control at this stage;

- Minimize raw material waste;

- Reduce failure rates and downtime;

- Guarantee time savings.

That’s why investing in textile technology is essential not only to correct errors but also to ensure financial health.

In this regard, Delta’s textile weaving machines are designed with the technical quality required to deliver excellence in this operation.

All machines are aligned with the Industry 4.0 concept to increase productivity through data integration. We believe that the development of the textile sector is driven by innovation, and every step in this direction raises the standard of excellence in the industry.

Below, we list Delta’s main solutions for the industrial weaving stage. Check them out!

1. Open Knitted Fabric Preparer

Delta’s Open Knitted Fabric Preparer (PMA500/PMT200) is a weaving machine designed to optimize this critical stage, offering automation and control that directly impact process quality.

With integrated motorization in the unwinder, puller, and spreader, the preparatory machine ensures perfect synchronization without creating tension on the material.

The inspection area, equipped with top and bottom lighting, provides a wide view to ensure that only material in perfect condition proceeds to finishing.

This guarantees:

- Versatility: preparation with integrated inspection in a single machine;

- High productivity: automation that eliminates manual bottlenecks;

- Labor optimization: reduced dependence on human intervention;

- Process standardization: uniform quality assurance across all batches;

- Reduced operational costs: less rework and textile waste.

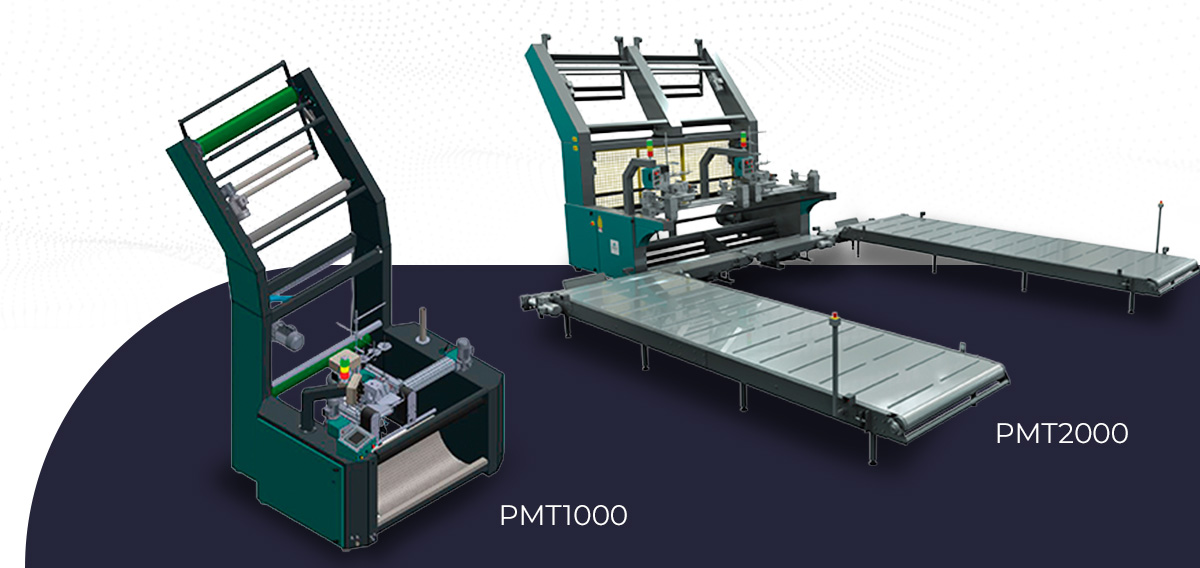

2. Automatic Tubular Knit Preparing Machine

When batch preparation for the dyeing process is manual or minimally automated, the result is operational bottlenecks, lack of standardization, and wasted valuable time.

Delta’s Automatic Tubular Knit Preparing Machines eliminate these issues, offering two options that adapt to your production volume and needs.

The Automatic Simple tubular knit preparing machine (PMT1000) reduces setup time and eliminates variations caused by manual intervention, ensuring each batch proceeds to dyeing with the same quality standard.

The Double Automatic Tubular Knit Preparing Machine (PMT2000) processes batches simultaneously, doubling capacity without compromising quality or significantly increasing the required space.

Both ensure reduced operational costs, standardization, and quality control from the preparation stage.

3. Plain Fabric Inspection Machine

The Plain Fabric Inspection Machine (REV110) was designed to optimize inspection activities. It stands out for its easy setup, which contributes to overall efficiency.

The solution offers advantages such as electronic drive with stretch control and a wide viewing area with top and bottom lighting for greater accuracy.

In addition, the machine’s alignment system is performed using high-definition sensors. All of this is available with three working modes: roll-to-roll, sheet-to-roll, and jumbo-roll-to-mini-roll.

The Next Step to Optimize Your Production

Investing in modern weaving machines is a strategic decision that directly impacts your industry’s growth potential.

That’s why Delta Textile Solutions develops solutions aligned with the Industry 4.0 concept, designed to address the real challenges of industrial weaving.

Each piece of equipment in our portfolio is engineered to deliver not just technology, but measurable results: less waste, higher productivity, and greater return on investment.

Discover how our machines can optimize your production and position your company ahead of the competition. Request a quote now!